19MWh Precision ESS | ±0.5% Voltage Stability for Smelters

Project ID: 05

Location: Gongyi, Henan, China

ESS Capacity: 19 MWh

Application: Critical Process Power Backup for Aluminum Production

Project Brief:

Deploys ultra-precise liquid-cooled ESS (cluster ΔT<3°C) to secure continuous power for energy-intensive smelting processes.

Key Challenges

• Extreme Thermal Sensitivity: Aluminum electrolysis requires voltage stability (±0.5%)

• High Ambient Heat: Plant temperatures up to 45°C challenge thermal uniformity

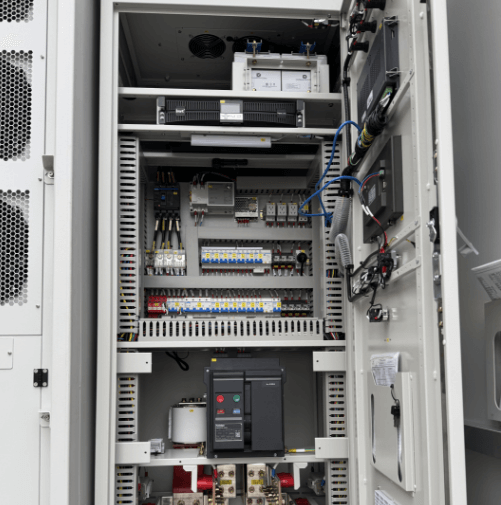

Technical Design (Solution Highlights)

Cluster-Optimized Thermal Management

▶ Per-Cluster Liquid Cooling: Independent coolant loops for each battery cluster

▶ ΔT <3°C Guarantee: AI-adjusted flow rates maintain unprecedented consistency

Tiered Safety Architecture

• Cluster-Isolated Fire Suppression: Vents + inert gas injection per unit (not whole system)

• 3-Stage Cascade Protection:

Pressure release at 150kPa

Coolant flooding if ΔT >5°C

Grid isolation in 200ms if thermal runaway is detected

Outcomes

✔ 100% Power Stability for 6,000kVA smelting load

✔ Zero Production Interruptions despite 3 grid failures

✔ ↑18% Battery Longevity vs. air-cooled systems

✔ CNY 2.3M/year Saved by avoiding voltage sags

Home

Home

30MWh Liquid-Cooled ESS | <5℃ ΔT & 99.8% Availability

30MWh Liquid-Cooled ESS | <5℃ ΔT & 99.8% Availability

Address: A401, Junxu Junchuang Park, 03A Qingyi Road, Nanhai District, Foshan City, Guangdong Province, China

Address: A401, Junxu Junchuang Park, 03A Qingyi Road, Nanhai District, Foshan City, Guangdong Province, China